Anaerobic treatment differs from conventional aerobic treatment in that no aeration is applied. The absence of oxygen leads to controlled anaerobic conversions of organic pollutants to carbondioxide and methane, the latter of which can be utilized as energy source.

The main advantages of anaerobic treatment are the very high loading rates that can be applied (10 to 20 times as high as in conventional activated sludge treatment) and the very low operating costs. Anaerobic treatment often is very cost-effective in reducing discharge levies combined with the production of reusable energy in the form of biogas. Pay-back times of significant investments in anaerobic treatment technologies can be as low as two years. Anaerobic treatment of domestic wastewater can also be very interesting and cost-effective in countries were the priority in discharge control is in removal of organic pollutants.

COD is basically a measure of organic matter content or concentration. The best way to appreciate anaerobic wastewater treatment is to compare its COD balance with that of aerobic wastewater treatment, as shown in Figure below.

Anaerobic Treatment:The COD in wastewater is highly converted to methane, which is a valuable fuel. Very little COD is converted to sludge. No major inputs are required to operate the system.

Aerobic Treatment:

The COD in wastewater is highly converted sludge, a bulky waste product, which costs lots of money to get rid of. Oxygen has to be continuously supplied by aerating the wastewater at a great expense in kilowatt hours to operate the aerators.

Anaerobic Wastewater Treatment:

Industrial wastewater anaerobic system treatment of wastewater is very well suited for industries discharging highly concentrated (over approximately 1,500 mg COD/l) wastewaters, with nitrogen concentrations that are not too high. The food and food processing industry, beer breweries, soft drink producing factories and paper producing or processing factories, and some chemical industries all discharge wastewaters of this type.

Many applications are directed towards the removal of organic pollution in wastewater, slurries and sludges. The organic pollutants are converted by anaerobic microorganisms to a gas containing methane and carbon dioxide, known as “biogas”.

Two major advantages of anaerobic wastewater treatment explain its progress at the expense of the classic aerobic activated sludge treatment:

- Sludge growth is significantly less compared with the aerobic treatment

- Considerable energy saving: no costly aeration and production of energy-rich biogas.

- Depending on the system scale the biogas (> 100 Nm³/hr) may be recovered to produce heat or electricity.

Other advantages:

- Lower nutrient requirements

- Lower plan area requirements because of higher volumetric loading rates

- Lower capital investment and overall operation costs.

The appropriate choice of anaerobic reactor type depends on the composition of the effluent. Successful anaerobic system wastewater treatment is only possible if the characteristics and specific problems for each individual wastewater are known in advance

How it works:

This process has been traditionally more complex and consequently harder to control than the aerobic biological process used in the classic activated sludge wastewater treatment. Better understanding of the microbiology of anaerobic processes has resulted in the successful development of new, improved and practical systems.

Anaerobic treatment is based on microbiological processes, namely methane fermentation, which occurs in an anaerobic environment.

Numerous species of bacteria have to cooperate in order to convert the organic pollution in the water to a mixture of methane (CH4)

and carbon dioxide (CO2), called biogas. The bacteria are generally present as sludge flocs or bacterial clusters (aggregates).

The main parameters determining the efficiency of the anaerobic activated sludge process are:

- Temperature

- BOD/COD ratio

- Sludge retention time

- Suspended solids concentration

- pH

- VFA/COD ratio

- Partial effluent recycle

- Nutrients

- Toxic compounds

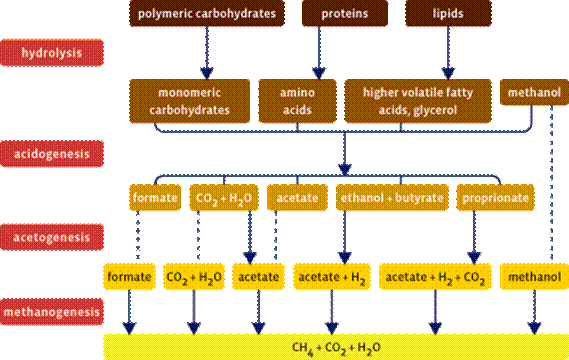

1. Hydrolysis & Acidogenesis:

Complex particulate and solubilized polymeric substrates (e.g. polysaccharides and proteins) are hydrolysed to simpler soluble molecules (amino acids and sugars). These products are then further catabolized by fermentative micro-organisms, to produce mainly volatile fatty acids (VFA), aldehydes, alcohols, carbondioxide and hydrogen.

2. Acetogenesis:

The majority of the fermentation products, except H2, CO2, formate and acetate, is further degraded by the acetogens to yield acetate and H2 and additional CO2. The acetogens grow in close association with the methanogenic bacteria.

3. Methanogenesis:

The final step in the anaerobic digestion is carried out by the methanogenic bacteria and is the formation of methane gas from acetate and from hydrogen and carbon dioxide.

4. Bioremediation:

Anaerobic system technologies are not only suitable for the removal of bulk COD they can also be utilized for the biodegradation or biotransformation of toxic priority pollutants. Microbial communities in anaerobic environments can either cause the oxidation of the pollutants resulting in its mineralization to

benign products (e.g. CO2) or they can cause the reductive biotransformation of pollutants to less toxic substances (e.g. dechlorination of polychlorinated hydrocarbons). Anaerobic bioremediation can take place in bioreactors, such as the case in the treatment of industrial effluents containing toxic pollutants. Or anaerobic bioremediation can take place in situ in groundwater or sediments at contaminated sites.

Figure: Example of a hazardous waste contaminated siteAmong the most successful applications of anaerobic treatment for the oxidation of toxic pollutants is the case of the treatment of effluent in the plastic industry containing high concentrations of terephthalate. These effluents are generally high in COD and aerobic treatment would result in excessive sludge production.

A complex microbial community of anaerobes is feasible to maintain in bioreactors permitting the total conversion of terephthalate to carbon dioxide and methane in high rate anaerobic bioreactors. Anaerobic technology has now been fully accepted as the main treatment technology for effluents of the polyethylene terephthalate (PET) industry.